Tamping Rammer Supplier

Our rammer compactor is designed with high impact force and lightweight construction for easy heat dissipation for a building site or construction project.

Key components are alloy steel, heat-treated for durability and abrasion resistance. Every rammer undergoes 500 hours of testing to ensure exceptional performance and long-term dependability.

- C&U Bearings

- 40-85cm Jump Stroke

- 12KN Impact Force

- Gasoline, Diesel and Electric Power

- Recoil Start

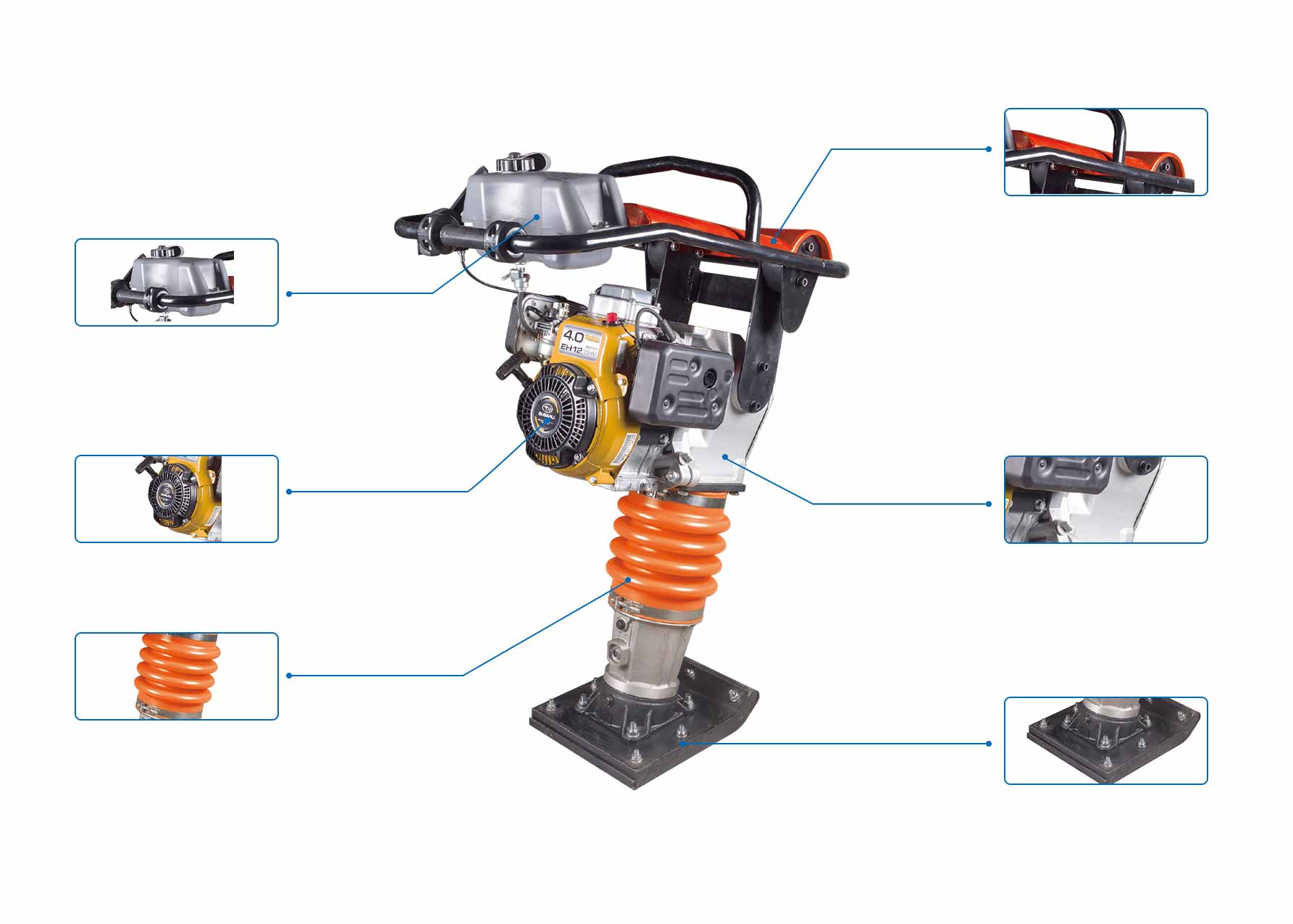

By Component

- Throttle Lever : Ensures smooth operation.

- Engine: Provides tamping power, using gasoline, diesel, or electric.

- Protective Cover: Provides structure and protects internal components from damage.

- Aluminum Crankcase: Adopted by cast aluminum case, easy for heat dissipation.

- Spring Mechanism: Converts power to tamping motion, with bellows or springs.

- Foot Plate: Steel or iron base plate compacts soil with durability.

By Power

Electric Motor

- Electric tamping rammer uses a 2.2kW motor, operate quietly, and produce no emissions, ideal for indoor spaces. They need a stable power source and minimal maintenance.

Gasoline Engine

- Gasoline tamping rammer uses unleaded gasoline (RON 90-95), offering versatility for construction. They ensure reliable performance, easy mobility, moderate fuel consumption.

Diesel Engine

- Diesel Tamping Rammer uses #0 or #2 diesel fuel, delivering maximum power and durability for compacting cohesive soils in highways, railways, and large infrastructure projects.

By Soil Types

Cohesive Soil (Clay & Silt)

- Recommended diesel or gasoline tamping rammer Cohesive soils retain moisture and require high-impact, localized compaction. Tamping rammers deliver strong vertical force, effectively compacting sticky soils.

Granular Soil (Sand & Gravel)

- Recommended gasoline or electric tamping rammer Granular soils have minimal cohesion and compact more efficiently with vibration rather than impact force.

Mixed Soil (Loam & Fill Material)

- Recommended gasoline or diesel tamping rammer The high-impact force of a rammer compacts mixed soils effectively. Adjust depth—cohesive layers need thinner lifts, while granular layers allow thicker compaction.

Applications

Road Construction & Repair

Tamping rammers compact the soil before asphalt or concrete paving, ensuring a solid and stable foundation. They help prevent surface cracking, uneven settling, and long-term structural failures in roads, sidewalks, and driveways.

Trench Compaction

Ideal for narrow and deep trenches, tamping rammers compact backfilled soil around underground utilities, preventing settlement that could cause pipe misalignment or collapse. Their high-impact force ensures proper soil density in confined spaces.

Pipeline & Sewer Projects

Used for compacting soil around pipelines and sewer lines, tamping rammers prevent shifting and voids that could lead to leaks or structural failures. They are essential to preserving the longevity and stability of underground infrastructure.

Backfilling Operations

After excavation work, tamping rammers compact backfilled soil to restore ground stability, preventing erosion and sinkholes. They are widely used in construction sites, utility repairs, and landscaping projects requiring soil reinforcement.

FAQ

How does a tamping rammer work?

It uses an engine-powered mechanism (gasoline, diesel, or electric) to generate vertical impact force, which compacts soil by reducing air gaps and increasing density.

What types of tamping rammers are available?

Tamping rammers come in gasoline, diesel, and electric models, each suited for different applications based on power, mobility, and environmental factors.

Which soil types are best for a tamping rammer?

Clay and silty soils work best with tamping rammers. They can also be used for mixed soils, but granular soils (sand and gravel) are better compacted with a vibratory plate compactor.

How deeply is dirt compactible with a tamping rammer?

A tamping rammer can typically compact soil layers (lifts) between 6 to 12 inches (15 to 30 cm) deep per pass, depending on soil type and moisture content.

How do I maintain a tamping rammer?

Regular maintenance includes checking the air filter, fuel system, engine oil, spark plug, and tamping foot. To guarantee longevity and avoid soil accumulation, clean after use.

Can asphalt be plowed under with a tamping rammer?

No, the purpose of tamping rammers is to compact soil. For asphalt, a vibratory plate compactor is a better choice.

How can I pick the best tamping rammer for my needs?

Choose based on soil type, project scale, and power source availability. Gasoline models are versatile, diesel is for heavy-duty work, and electric suits noise-sensitive areas.